| | B-52s in the Desert

(Topped off with a B-58) In the course of our research and searching in the desert around Edwards AFB we stumbled onto a bit of a mystery. Directly south for Edwards AFB at the edge of Rogers Dry Lake Bed are two B-52s and a B-58. Now it's not every day that you come across a B-52 in the desert, let alone two of them with a B-58 nearby, and while it was obvious that these were not "crashes," we were interested in how these aircraft came to be where they were and why one of them had apparently been blown apart.

| An aerial view of the two B-52s. About 200 yards to the west is a B-58.While they may have been a mystery to us. Someone, somewhere knew the details, and we set out to find out ourselves. |

Click on above for enlarged view

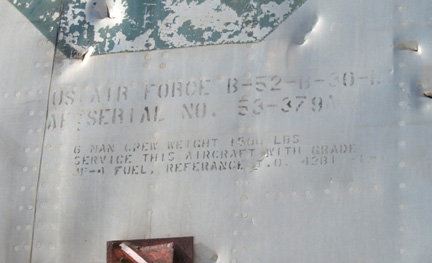

| Why are the B-52s There in the First Place?One of the B-52s is an RB-52B-30-BO Stratofortress (Serial Number 53-0379A) which transferred to AFFTC in 1965, where it was used extensively for "Barrier Tests". It was deleted from USAF inventory in 1970. Now at south end of Rogers Dry Lakebed it sits there in its current (abused) condition.The other is B-52E-55BW (Serial Number 57-0119) which was loaned to General Electric for engine tests in the 60s and it now in three pieces just off the lake bed. This particular 'Buff' was used to test the General Electric TF-39 for the Lockheed C-5A "Galaxy" program. The TF-39 was mounted on the right inboard engine pylon in place of the two J57s normally installed. | The simple answer is, they were used for "Barrier Tests" (it's painted right on the side of the aircraft.) The barrier tests were a series of tests where aircraft of various types and sizes were literally caught in a net when landing. We don't have all the information on the entire program, but suffice to say the Navy does use a barrier system on their aircraft carriers to stop (catch) any jets that miss the arresting cables when landing.

|

| At Edwards, barrier landings are used for safe aircraft landings for in-flight emergencies. They save aircraft and lives, and minimize untold damages to flight systems saving millions of taxpayer dollars. The 68 miles of paved and dry lake runways already in existence there, along with the two aircraft arresting systems, known as barriers, located at the approach ends of runways 04 and 22 provide a safety net for tail-hook equipped aircraft. | Recently a new barrier system became operational at Edwards, the newest since the BAK 13 used for testing during the 60s and 70s at South Base. The BAK 12s were installed January 2000 and have saved two aircraft from in-flight emergencies: in July 2000, a NASA F-18 with a collapsed rear landing gear; and in January 2001, an F-15 with hydraulic failure. |

Seen here is the barrier undergoing an annual test.

| Barrier Test FacilityThe facility (currently mothballed) consists of barrier pits on both sides of the South Base runway approximately 100 by 50 feet sunk into the ground approximately 15 feet. The pits are connected underground by a walk-through tunnel under the runway. The floors of the pits are equipped with bolt-down rails to facilitate a wide variety of barrier system configurations.The walls of the pits are also equipped with bolting provisions to accommodate any sheaves necessary for the routing of the barrier tapes. The roof of each pit is at ground level and can be rolled back to accommodate installation and removal of large pieces of equipment. Adjacent to the runway and next to the southern pit is a reinforced barrier test control booth to provide safe control of testing.Also adjacent to the runway and barrier pit on the south side is a facility used for storage and engineering space. A fenced compound is within 150 feet of the facility, providing for outdoor storage of large equipment.A BAK-13 is installed approximately 100-feet to the west of the barrier facility with fair-lead tubes and sheaves (currently this installation is inoperable). A minimum amount of the South Base runway is open at this time with plans to renovate the runway back to full bearing capacity. The facility is capable of supporting a wide variety of barrier setups, BAK-9 through BAK-14 including mobile arresting gear evaluations. Instrumentation consists of high-speed photography from reinforced locations, speed trap, cable runout, loads, etc. | Now That's a BIG EngineThis 'Buff' (57-0119) was used to test the General Electric TF-39 engine for the Lockheed C-5A "Galaxy" program, starting in 1965. The TF-39 was mounted on the right inboard engine pylon in place of the two J57s normally installed. The high-bypass turbofan was a giant leap in aircraft engine design, offering high thrust levels (43,000 pounds) and revolutionary fuel efficiency. In other words, it had as much thrust as four J57 turbojets on a standard production B-52E (probably 2.5 times more powerful than any previous jet engine). The TF-39 was also the first high-bypass ratio turbofan engine. It is an engine that gulps about 42 tons of air per minute at takeoff power!The TF-39 included such pioneering technological accomplishments as an 8-to-1 bypass ratio, 25-to-1 compressor pressure ratio, a 2,500°F turbine temperature made possible by advanced cooling techniques, and a GE-designed thrust reverser. It had a dual-spool layout as well as a variable stator, with its big fan providing 85 percent of the thrust. The dual-spool arrangement gave the fan its own turbine for power, separate from the rest of the engine. The compressor had 16 stages, or rows of blades. Its fan, compressor, combustor, turbine, and exhaust system were almost perfectly matched, and each system was significantly more efficient than its predecessors.These three design principles—dual-spool layout, variable stators, and the turbofan—remain in use to this day. All three can even appear in the same engine, as with the TF-39. The dual-spool design gives high thrust with good fuel economy. Variable stators allow efficient operation at all flight speeds. The big forward fan reduces noise, further improves fuel economy, and produces much of the thrust. In turn, the thrust of engines continues to increase. |  B-52E #57-0119 Landing at Edwards AFB |

|  B-52E #119 In Flight |

|  The TF-39 engine, mounted on B-52E #119 |

|

The General Electric TF-39 engine |

| The Russian ConnectionAfter the test projects, they were completed the B-52s were put out to pasture. Then in 1991, the Strategic Arms Reduction Treaty (START) put into motion a reduction in the number of "Strategic Nuclear Delivery Vehicles." As part of complying with this treaty, the U.S. began the task of destroying over 350 B-52s. C, D, E, F and G model B-52s have been destroyed. H models are still part of the Air Force fleet and the venerable B-52 will probably set longevity records as it continues to serve far into the future. The START treaty also called for verification by "National Technical Means," e.g. satellite. The B-52s being destroyed are chopped into sections and left sitting for 90 days so that Russian and Ukrainian satellite surveillance systems could verify the number being destroyed.However, one day, a photo interpreter in the former Soviet Union noticed the "strategic weapons" ready for activation at a moments notice on the edge of an active U.S. Air Force Base. Little did they know the real condition of either aircraft. The Russians insisted that according to treaty, one of the B-52's had to be rendered inoperable. So, one day some lucky guys from Edwards AFB got to blow up their first B-52 (the unlucky 0119). After placing some high explosive in the fuselage (and perhaps running like hell) the B-52 was rendered inoperable to the satisfaction of the Russians. (In fact, we found and talked to the guy who set the charges!) |

|

|

|

|

|

| | The B-58 (Snoopy to its friends) | The B-58A (serial number 55-0665 and nicknamed Snoopy) was the sixth B-58 to be built and arrived at its current location a little differently. It was used, at one time, to test radar systems for the GAR-9/AIM-47 missile for the F-108 Rapier and later the YF-12A. This B-58 first flew September 28, 1957 and was delivered to the USAF on February 15, 1958. |

Click for an enlarged photo

|  | "Snoopy" in flight, big black nose and all... |

| On October 17, 1958, Convair received a contract from Hughes and the USAF to manufacture two special pods for GAR-9 missile launch tests and to modify one B-58 for AN/ASG-18 test-bed work. Snoopy was selected for the modifications. In February 1959, it began modifications to begin life as a test bed.In order to fit the rather large AN/ASG-18 fire control system into the B-58A, nearly seven feet had to be added to the overall length of the aircraft (that explains why it looks a little odd). Internal changes had to be made in the second crew station and elsewhere to accommodate the associated instrumentation and control equipment. | The flight testing of the radar began in early 1960, but the first GAR-9 launch did not take place until May 25, 1962. By late 1963, the YF-12A flight test program was sufficiently well advanced that it was concluded that it was now possible for future GAR-9 missile launches to take place from the YF-12A itself. The last B-58 GAR-9 launches took place in February of 1964.After the completion of the ASG-18/GAR-9 test program, the special modifications were removed from Snoopy. However the long nose was retained. Snoopy was eventually placed out in the open on the photo test range at Edwards AFB. We were told it was placed here for use as a ground target for some other test equipment.Today it sits quietly in the desert, home for a few desert owls and a curiosity to those who take note of it. |

Note the extra long nose on this B-58

|

"Snoopy" can still be seen ready for action below the cockpit.

|

A piece at a time, "Snoopy" gives way to the desert |

"Snoopy", with "Snoopy" in the background |

|